Thermal Remediation - Electrical Resistance Heating

Electrical Resistance Heating (ERH) utilizes heating produced by passing electricity through the subsurface to mobilize contaminants, which can then be extracted. ERH has gained wide acceptance and is commonly used for treatment of source zones with volatile organic contaminants. The most common applications have been for chlorinated solvents sites in difficult matrices, such as silt and clay settings. Heating is produced by passing alternating current through the formation between electrodes, which are customized to site conditions. ERH can be combined with less aggressive methods for complete site and plume restoration (e.g., see Thermal Remediation - Combined Remedies).

Related Article(s):

- Thermal Remediation

- Steam Enhanced Extraction (SEE)

- Thermal Conduction Heating (TCH)

- Thermal Remediation - Combined Remedies

CONTRIBUTOR(S): Dr. Gorm Heron

Key Resource(s):

- Six-Phase Soil Heating for Enhanced Removal of Contaminants: Volatile Organic Compounds In Non-Arid Soils Integrated Demonstration[2]

- Electro-Thermal Dynamic Stripping Process for In Situ Remediation Under an Occupied Apartment Building[3]

Introduction

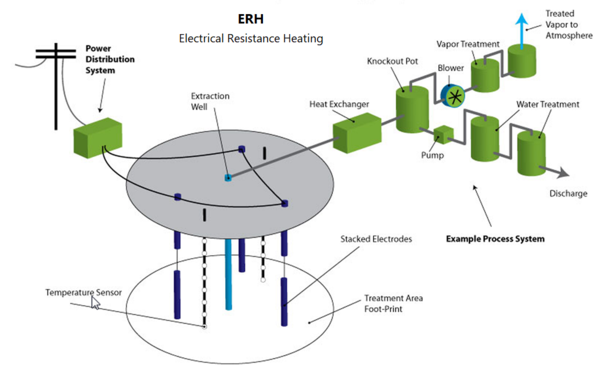

The principle of ERH is to heat the treatment volume by passing electricity through it, causing the soil and water to heat to temperatures that mobilize the contaminants for extraction (Figure 1). Typical ERH systems utilize three-phase alternating current applied to buried electrodes spaced systematically throughout the thermal treatment zone (TTZ) in a triangular pattern. An early variation of ERH used six phases of electricity. For sites with treatment zone thickness over 5 meters (16 ft), multiple elements may be stacked within an electrode borehole to customize applied voltages to the subsurface. Contaminants are removed by extraction from the electrodes and/or from separate extraction wells. A cooling and treatment system is used to separate and treat the extracted water, steam, air and contaminants on site.

ERH requires the presence of soil moisture and groundwater to conduct electricity, and therefore can be applied at low (<100°C) to moderate (~100°C) temperatures to accomplish the remediation of a wide variety of contaminants, both above and below the water table[1].

In a modification of ERH water is extracted and treated in separate wells, then recirculated into custom electrodes to facilitate heating by inducing convection[3]. This expands the use of ERH to more permeable formations, since some of the injected water is turned into steam, which adds to the heating.

Applications

Because ERH is based on heating by electrical resistance, it can be used above and below the water table. Water is needed for facilitating heating, so target temperatures are restricted to local boiling point temperatures. ERH has been used most frequently to treat volatiles such as trichloroethene (TCE) and tetrachloroethene (PCE). Example contaminants of concern include:

- Chlorinated solvents

- Non-aqueous phase liquids (NAPLs), both dense and light

- Pesticides

- Munition compounds

- Polycyclic aromatic hydrocarbons (PAHs)

- Fuels and heavy hydrocarbons (partial removal)

- 1,4-Dioxane

Target treatment temperatures are typically 90-100°C. Additionally, low temperature ERH has been implemented at sites where the remedial goal is enhancing abiotic and biotic processes, such as the biodegradation of chlorinated solvents or hydrolysis of munition compounds.

ERH is scalable and well-suited for small shallow sites or large deep sites, and when properly implemented it can lead to effective site closure. ERH is very tolerant of subsurface heterogeneities and performs as well in low permeability clays and silts as higher permeability sands and gravels. When combined with Steam Enhanced Extraction (SEE), effective solutions are available for sites with substantial groundwater flow as well[4]. When the treatment zone is well delineated, and the ERH system designed and implemented correctly, high removal efficiencies can be achieved.

Example Case Studies

ERH has been applied to over 200 sites worldwide. Example cases include:

- Savannah River Site: ERH (6 phase heating) was used to demonstrate effectiveness for a chlorinated solvent hotspot[2].

- Lawrence Livermore National Laboratory – Gas Pad: ERH was combined with steam injection to demonstrate treatment of a deep gasoline spill[5].

- Young-Rainey STAR Center: ERH and steam enhanced extraction was combined for treatment of a 35-ft deep source zone in complex geology[4].

- Paducah Gaseous Diffusion Plant: ERH (6 phase heating) was used to demonstrate heating to 100 feet below ground surface, the deepest application at that time. Multiple elements were installed within the electrode borings.

- East Gate Disposal Yard Site: ERH was used at three different DNAPL (TCE) and LNAPL (petroleum products, oils and lubricants) source areas. Significant reductions of contaminant mass (greater than 99%) were observed within the treatment areas and downgradient. One of the source area ERH applications resulted in over 100,000 lbs of volatile organic compound (VOC) mass removed. Additionally, biotic and abiotic degradation processes were observed throughout the range of operating temperatures, which lead to a heat enhanced biodegradation demonstration at the same site.

- Sandstone Site in Eastern Pennsylvania: ERH treatment of a 90-ft thick sandstone bedrock treatment interval took 82 days to achieve remedial goals and meet target temperatures.

- Redstone Arsenal: ERH was used for several DNAPL source area (TCE and chlorobenzene) remediations in karst limestone.

- Confidential Site: In situ treatment of 1,4-Dioxane using ERH, resulting in a greater than 99.8% removal from the subsurface due to steam stripping.

- Sioux Army Depot Site: ERH used to demonstrate effective hydrolysis of RDX, TNT, HMX and other munitions compounds.

These case studies illustrate the type of sites addressed with ERH. Common themes are (1) significant source contamination, (2) advances with heat enhanced abiotic and biotic processes.

Summary

Electrical Resistance Heating can be used to treat volatile organic compound (VOC)-contaminated source zones to low levels in tight formations such as silts and clays. By heating the target volume to near the boiling point of water, contaminants are volatilized and removed for treatment or destruction on site.

References

- ^ 1.0 1.1 Buettner, H.M. and Daily, W.D., 1995. Cleaning Contaminated Soil Using Electrical Heating and Air Stripping. Journal of Environmental Engineering, 121(8), pp. 580-589. doi:10.1061/(asce)0733-9372(1995)121:8(580)

- ^ 2.0 2.1 Gauglitz, P.; Roberts, J.; Bergman, T.; Schalla, R.; Caley, S.; Schlender, M.; Heath, W.; Jarosch, T.; Miller, M.; Eddy-Dilek, C.; Moss, R.; Looney, B., 1994. Six-Phase Soil Heating for Enhanced Removal of Contaminants: Volatile Organic Compounds In Non-Arid Soils Integrated Demonstration, Savannah River Site. Report No. PNL-10184, UC-406. Pacific Northwest Laboratory, Richland WA, USA. 72 pages. doi: 10.2172/10193982 Report.pdf

- ^ 3.0 3.1 McGee, B.C., 2003. Electro‐Thermal Dynamic Stripping Process for in situ remediation under an occupied apartment building. Remediation Journal, 13(3), pp. 67-79. doi:10.1002/rem.10075

- ^ 4.0 4.1 Heron, G., Carroll, S. and Nielsen, S.G., 2005. Full‐Scale Removal of DNAPL Constituents Using Steam‐Enhanced Extraction and Electrical Resistance Heating. Groundwater Monitoring and Remediation, 25(4), pp. 92-107. doi:10.1111/j.1745-6592.2005.00060.x Free Download

- ^ Newmark, R.L. (ed.) 1994. Demonstration of Dynamic Underground Stripping at the Lawrence Livermore National Laboratory Gasoline Spill Site. Final Report UCRL-ID-116964, Vol. 1-4. Lawrence Livermore National Laboratory, Livermore, CA.